This is a known and relatively common issue on the 2022 Audi A5 equipped with the 2.0 TDI DTPA engine is a distinct whistling noise that originates from the engine bay. This sound is not constant, but typically appears under specific conditions, such as during sharp acceleration or in the moment the throttle is released after building up engine revs.

The problem comes from the nuts holding the exhaust manifold to the engine head. Over time, the nuts holding the manifold in place can begin to lose their proper torque and become loose. When this occurs, a small gap forms between the manifold and the engine block. The high-pressure exhaust gas escaping through this tiny opening is what creates the audible high-pitched whistle.In most cases, the issue is with the nuts for the first and fourth cylinders on the exhaust manifold.

Symptoms of the Fault

- A distinct, whistling sound coming from the engine bay.

- The sound is most noticeable during rapid acceleration or a sudden release of the throttle.

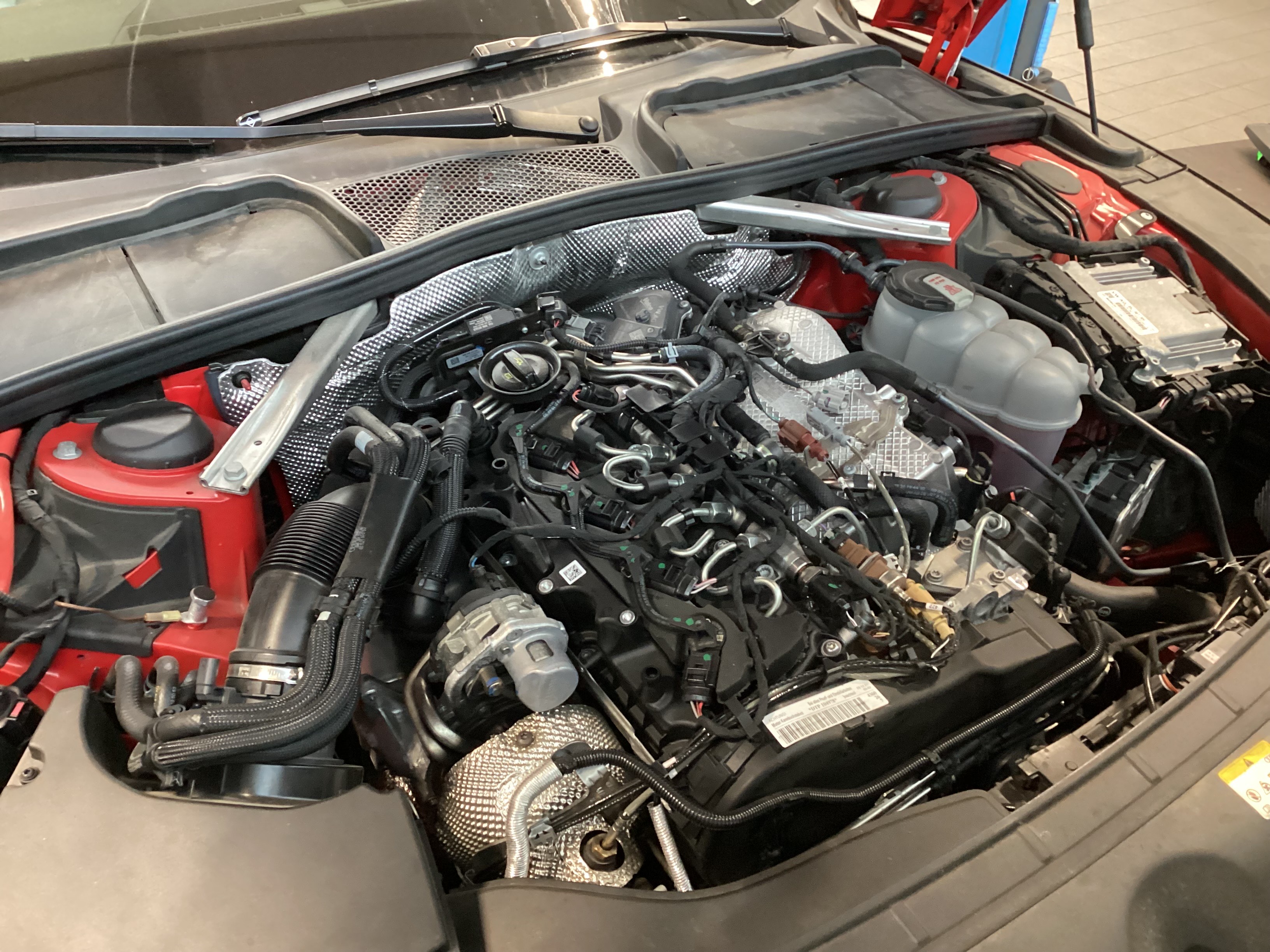

- Visible signs of an exhaust gas leak, which look like soot marks on the exhaust manifold where it bolts to the cylinder head.(As highlighted in the photograph below, the location of the exhaust leak has been marked.For this specific car, the problem was the nuts on the very first cylinder of the exhaust manifold)

The Repair Process

The repair process should begin with a inspection of the exhaust manifold for any visible signs of leaks, paying close attention to the area around the first and fourth cylinders. A direct visual check can be challenging due to the engine's compact design and surrounding components, but by using small inspection mirrors and a suitable lamp, it is possible to identify if an exhaust gas leak is present.

If a leak is confirmed, the repair involves replacing the exhaust manifold nuts. This is a time-consuming task due to the limited workspace within the engine bay. The procedure becomes significantly more challenging

on Quattro models, where drivetrain components make accessing some bolts from underneath extremely difficult. During the removal of the manifold nuts, it is frequently observed that several have lost their specified fastening torque, which serves as confirmation of the leak's origin.

While it is technically possible to perform this repair by only replacing the accessible manifold nuts, this is not the recommended procedure for a lasting solution. For a complete and reliable repair, the best practice is to remove the entire exhaust manifold and turbocharger assembly. This allows for the proper cleaning of the mating surfaces on both the cylinder head and the manifold.

For reassembly, you will need to use a new gasket and a complete set of ten new nuts to ensure a proper, leak-free seal. It's important to know that nine of these nuts are a standard size, while one is slightly longer. The single longer nut needs to be placed in its specific location on the upper stud of the first cylinder. Once all the nuts are in place, finish the job by tightening all ten of them down properly to create a solid seal.