If you are working on a 2023 or newer Volkswagen Caddy with a manual transmission, you might run into a specific clutch issue that is becoming a regular sight in workshops. At first glance, it often looks like a standard slave cylinder failure, but the real cause is a manufacturing defect inside the gearbox itself that requires more than just a simple part swap.

This issue is specific to manual gearboxes manufactured up to February 7, 2023. You can verify this by looking at the production code stamped on the gearbox housing. For example, a code like 230520 64 indicates a production date of May 20, 2023. If the ending number is 64, it belongs to the affected batch. If the number is 48 instead of 64, the gearbox was manufactured differently and should not suffer from this specific defect.

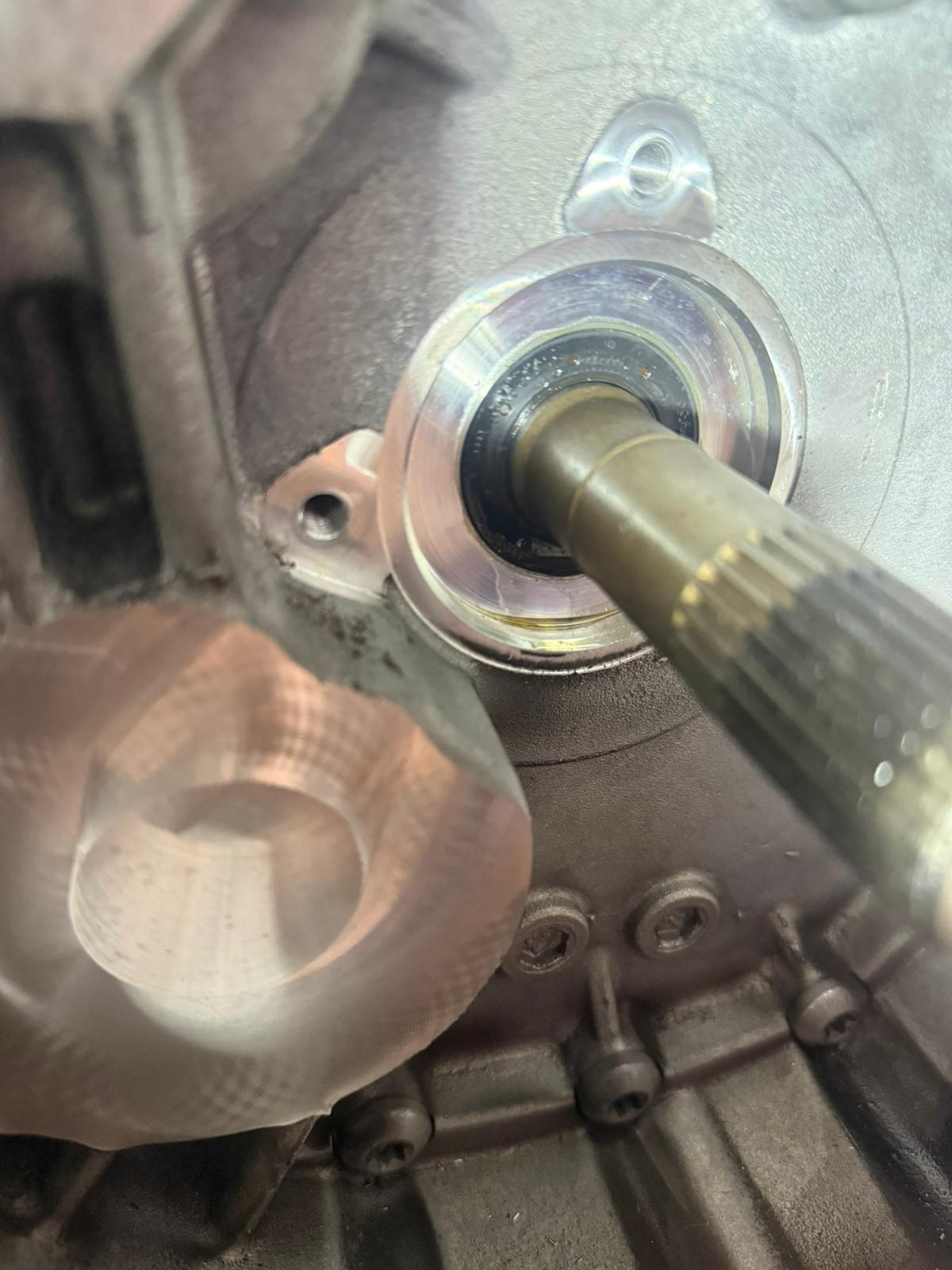

The root of the problem is a manufacturing error where the input shaft area where the oil seal sits was not properly smoothed down. Over time, this rough surface acts like sandpaper against the input shaft oil seal, eventually tearing it and allowing gearbox oil to leak into the bellhousing, as shown in the photo below where the oil is visibly escaping through the seal. This oil contaminates the clutch disc and the slave cylinder, leading to the failures mentioned above.

Symptoms of the Fault

The most common signs of this fault include a sudden difficulty in engaging gears, especially first and reverse. In many cases, the clutch pedal will eventually stay stuck to the floor and If you look under the vehicle, you will likely notice a gearbox oil leak dripping from the bellhousing.

The Repair Process

To fix this properly, you must first remove the gearbox and inspect the slave cylinder for oil. If a leak is confirmed, it is best practice to replace the clutch master cylinder, the hydraulic hose, and the slave cylinder together. This is because gearbox oil can mix into the clutch hydraulic system, and if that contaminated fluid stays in the lines, it will quickly ruin the seals on your new parts.

Before reassembling, you have to polish the input shaft surface. Take 600 grit sandpaper and carefully smoothen the area on the shaft where the oil seal sits. You can do this by wrapping the sandpaper around the shaft and rotating it by hand until the surface is polished. Perform two sets of 30 rotations, using a new sandpaper for each set. Be extremely careful to only smooth the surface and not to remove too much material. over-sanding the shaft can change the diameter and lead to further oil leaks. You must also ensure that no debris or sandpaper grit enters the gearbox through the input shaft hole during this process. Once the shaft is smooth, install a new oil seal and a new slave cylinder before refitting the gearbox and bleeding the system thoroughly.